As the construction industry evolves to address climate change, one concept has moved to the forefront of sustainable design: embodied carbon. Understanding what it is—and how our material choices affect it—is key to reducing our environmental impact. Among the many building options available today, timber frame construction stands out as a powerful tool in lowering our carbon footprint.

In this breakdown, we will look into embodied carbon meaning and relevance in construction and how the future may look.

As the construction industry evolves to address climate change, one concept has moved to the forefront of sustainable design: embodied carbon. Understanding what it is—and how our material choices affect it—is key to reducing our environmental impact. Among the many building options available today, timber frame construction stands out as a powerful tool in lowering our carbon footprint.

In this breakdown, we will look into embodied carbon meaning and relevance in construction and how the future may look.

What is Embodied Carbon?

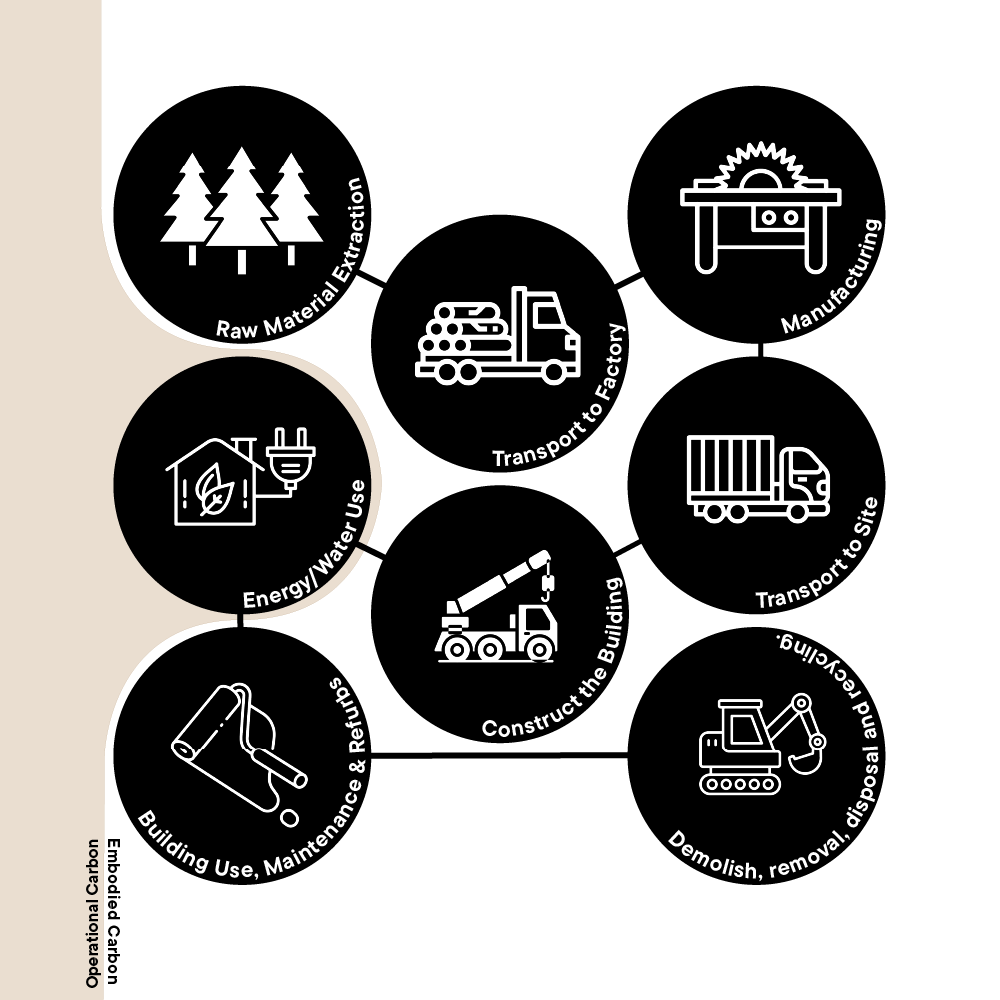

Embodied carbon is the hidden carbon cost of a building. Unlike operational carbon, which comes from heating, cooling, and powering a structure over its lifetime, embodied carbon refers to the greenhouse gas emissions generated before the building is even used.

This includes emissions from:

Raw material extraction – mining, logging, or harvesting resources.

Manufacturing processes – transforming raw materials into building products.

Transportation – moving materials from supplier to site.

Construction activities – machinery use, site operations, and waste.

End-of-life processing – demolition, disposal, or recycling of materials.

Once emitted, embodied carbon is locked in and cannot be reduced—making it critical to choose low-carbon materials from the start.

The Carbon Advantage of Timber

Natural Carbon Storage

Trees act as nature’s own carbon capture technology. Through photosynthesis, they absorb carbon dioxide (CO₂) from the atmosphere, storing it as carbon in their trunks, branches, and roots.

One cubic meter of wood stores roughly 1 tonne of CO₂.

That carbon remains locked away for the lifespan of the building—sometimes for more than a century.

This creates a carbon bank inside our built environment, effectively turning buildings into long-term carbon storage facilities.

Comparing Construction Materials

When we compare materials by the average CO₂ emissions they generate per tonne, the environmental case for timber becomes clear:

| Material | Avg. CO₂ Emissions (per tonne) |

|---|---|

| Steel | 1.9 tonnes CO₂e |

| Concrete | 0.9 tonnes CO₂e |

| Brick | 0.8 tonnes CO₂e |

| Timber | Potentially carbon negative |

Unlike steel, concrete, or brick, timber can store more CO₂ than is emitted in its processing, making it one of the few carbon-negative building materials available.

Manufacturing Impact

Producing timber components has a much smaller environmental footprint than manufacturing steel or concrete:

Lower energy demand – Timber processing is less energy-intensive.

Minimal water usage – Particularly compared to cement production.

Reduced transportation emissions – Timber’s lighter weight means fewer trucks and less fuel.

Lower on-site machinery use – Prefabricated timber frames require less heavy lifting equipment.

The result? A construction process that’s cleaner, quieter, and often faster.

Whole-Life Carbon Assessment

When we zoom out to consider the entire lifecycle of a building, timber’s benefits grow even clearer:

Negative carbon potential – Timber frame structures can offset their own embodied carbon through storage.

Recyclable & reusable – Structural timber can be repurposed into new buildings or products.

Biodegradability – End-of-life timber can decompose naturally, avoiding landfill methane emissions.

Supports the circular economy – Components can be recovered, refurbished, and reintroduced into the supply chain.

Industry Progress

The timber sector continues to innovate, further reducing embodied carbon:

Digital carbon tracking systems – Allowing architects and clients to measure and verify carbon savings.

Sustainable forestry management – Ensuring forests are replanted and biodiversity is maintained.

Advanced manufacturing – CNC cutting and modular construction improve material efficiency.

End-of-life planning – Designing buildings for easy disassembly and reuse.

Looking to the Future

The construction industry is moving towards a low-carbon future, with trends that will accelerate timber’s adoption:

Mandatory carbon reporting – Transparency on embodied carbon will influence design choices.

Tougher emissions regulations – Incentivising the use of low-carbon materials.

Carbon pricing mechanisms – Making high-emission materials more expensive.

Enhanced sustainability certifications – Recognising and rewarding carbon-conscious design.

Final Thought:

Choosing timber frame construction isn’t just about aesthetics or speed—it’s a strategic decision to lower embodied carbon and fight climate change. Every cubic meter of wood used in place of high-carbon materials is a step towards a building industry that doesn’t just minimise harm but actively benefits the planet.

Learn more about the carbon storage of timber here:

https://www.forestresearch.gov.uk/research/carbon-storage-in-wood/