What is MVHR?

MVHR is a whole‑house ventilation system that:

Extracts warm, stale air from wet rooms (kitchens, bathrooms, utility rooms)

Supplies fresh, filtered air to habitable rooms (living rooms, bedrooms, offices)

Transfers heat from the outgoing air to the incoming fresh air via a heat exchanger

The two air streams never mix, but heat is recovered — typically 75–95%, depending on system quality and installation.

Why MVHR Matters in Modern Homes

Airtightness has changed everything.

Modern construction — particularly timber frame — is increasingly airtight. This is essential for:

Energy efficiency

Predictable thermal performance

Compliance with Part L, SAP, and low‑carbon standards

However, airtight buildings must be ventilated deliberately. Relying on trickle vents or intermittent extract fans can lead to:

Poor indoor air quality

Condensation and mould risk

Heat loss through uncontrolled ventilation

MVHR solves this by providing continuous, balanced ventilation with minimal heat loss.

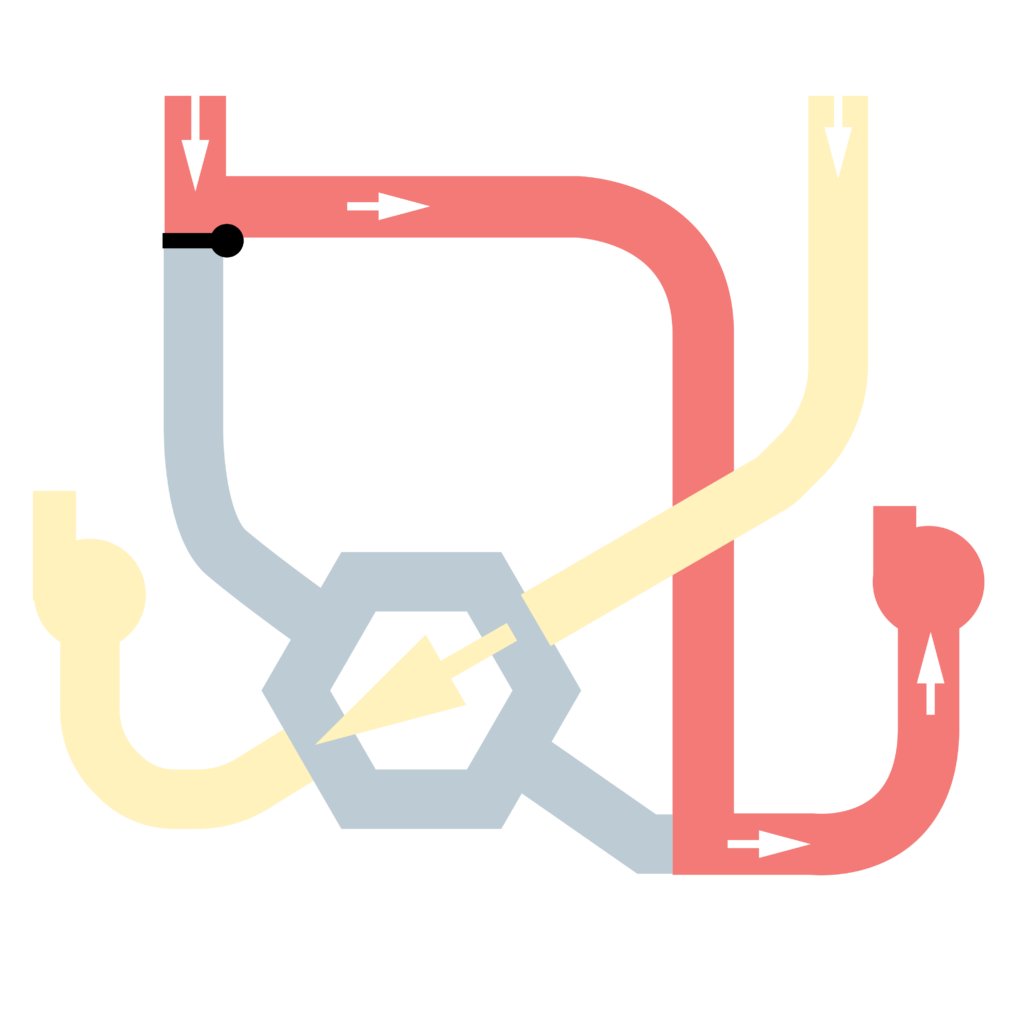

How does it work?

Have a look through the key components of the MVHR system, below:

MVHR Unit

The central point, where the heat exchanger is houses and fans provide flow/exhaust pressure. The most important component in the system.

Feed/Exhaust Ducts

The pipework which moves the hot and cold, stale and fresh air around the system. These can be rigid, semi rigid, or flexible (we’ll touch on this later.)

They can also be round, square, or rectangular.

Plenums

Connects central, wider single ducting with a greater number of narrower ducts to feed individual rooms.

Think of it as a reducer from the main ‘arteries’ of the system down to the wider spread, smaller ‘veins’.

Intakes and Valves

The only visible components of the system. The vents provide decorative face to inlet/exhaust ducts in rooms. Some models also allow you to control flow rates.

These are available in many styles – from simple and contemporary to traditional.

Filters

Removes dust, pollen and dirt from the air, ensuring air quality in the home is improved and kept consistent. These are easily accessible and replaced periodically.

Key Benefits of MVHR:

-

Energy Efficiency

Recovers heat that would otherwise be lost.

Reduces space‑heating demand.

Particularly effective in low‑energy and Passivhaus‑style buildings. -

Improved Air Quality

Continuous removal of moisture, CO₂, and pollutants.

Filtered incoming air (ideal for urban or pollen‑sensitive environments)

No reliance on occupants opening windows. -

Comfort

Even air distribution.

Fewer draughts.

Stable internal temperatures. -

Building Fabric Protection

Reduced condensation risk.

Supports long‑term durability of timber structures.

Helps maintain design airtightness performance.

Is MVHR Right for Every Building?

MVHR is most effective when:

Airtightness is typically ≤ 3.0 m³/hr/m² @ 50Pa (ideally ≤ 1.5)

The building has a continuous airtight layer

Ventilation is considered early in design

It may be less suitable for:

Very leaky retrofit properties (unless airtightness is improved)

Projects where duct routes cannot be accommodated

In timber‑frame construction, MVHR is often an ideal pairing due to the ease of integrating ducts within floor zones, service cavities, and panel layouts.

MVHR and Building Regulations (UK)

MVHR systems are recognised under Approved Document F (Ventilation) as a compliant whole‑house ventilation strategy.

Key considerations:

Systems must be designed, installed, commissioned, and balanced correctly

Commissioning certificates are required

SAP assessments must reflect actual system efficiency and specific fan power (SFP)

Poor design or installation can undermine performance — MVHR is not a ‘fit‑and‑forget’ product.

System Quality, Efficiency and Why Specification Matters

Not all MVHR systems are created equal. Performance on paper does not always translate to performance in use.

High‑quality MVHR units typically offer:

Heat recovery efficiencies of 85–95% (tested to recognised standards)

Low Specific Fan Power (SFP), reducing electrical consumption

Quiet, well‑balanced EC motors

Effective filtration options (including pollen and fine particulates)

Intelligent controls and automatic summer bypass

Lower‑quality systems may meet minimum regulatory requirements but often suffer from:

Higher running costs

Increased noise

Reduced real‑world heat recovery

Shorter service life

In airtight timber‑frame buildings, where ventilation performance directly affects comfort, energy use, and fabric health, the quality of the MVHR unit is not an area to value‑engineer aggressively.

Summer Bypass: Comfort All Year Round

A key feature of higher‑quality MVHR systems is called summer bypass.

During warmer months, internal spaces can retain unwanted heat — particularly overnight. A summer bypass allows the system to temporarily divert incoming fresh air around the heat‑exchange core, rather than warming it with extracted air.

This enables:

Cooler night‑time air to be supplied directly indoors.

Reduced risk of overheating. (read more about overheating here.)

Improved summer comfort without relying on mechanical cooling.

Importantly, summer bypass is automatically controlled on good‑quality systems, responding to internal and external temperatures. Poorly specified units may lack bypass entirely, or rely on crude manual operation, limiting effectiveness.

Zehnder have a great article which looks at summer bypass in more detail.

Design Considerations

(The factors that can make-or-break your system.)

Early Co-Ordination

MVHR should be considered at concept or technical design stage, not retrospectively.

Key coordination points:

Plant location (loft, utility, cupboard)

Duct routes and depths

Interaction with structure, joists, and service zones

Acoustic strategy

Ductwork Design

Short, straight runs are best

Rigid or semi‑rigid ducting preferred over flexible

Correct sizing to minimise pressure drops and noise

Airtightness and Sealing

Penetrations through the airtight layer must be detailed and sealed

Poor sealing negates system efficiency

Installation Quality

(No compromises here.)

Even the best MVHR unit will underperform if installed poorly.

Common issues include:

- Crushed or excessively flexible ducts

- Poorly sealed joints

- Incorrect commissioning and balancing

- No allowance for maintenance access

In off‑site timber‑frame projects, many of these risks can be reduced through:

- Pre-Planned Service Zones

- Factory‑installed airtightness measures

- Clear coordination between frame design and M&E strategy

Maintenance and User Considerations

MVHR systems require minimal but essential maintenance:

Filters typically replaced every 6–12 months

Occasional inspection of vents and terminals

Occupants should be:

Shown how the system works

Advised not to turn it off

Provided with clear handover information

A well‑understood system performs better over its lifetime.

MVHR and Timber‑Frame Buildings. Perfect partners.

Timber‑frame buildings are particularly well‑suited to MVHR because:

Airtightness is easier to achieve and maintain

Service cavities can be designed into wall and floor build‑ups

Factory precision supports repeatable quality

When structure, airtightness, and ventilation are designed as a single system, performance on site becomes predictable rather than theoretical.

MVHR and timber frame structures combined are also a fantastic way of achieving Passivhaus certification or Passivhaus principles.

Conclusions

MVHR is not just a piece of kit — it is part of a wider building‑performance strategy. When properly designed and integrated, it:

Enhances comfort and wellbeing

Protects the building fabric

Reduces energy demand

Complements airtight timber‑frame construction

The key is early design, proper coordination, and quality installation. Get those right, and MVHR becomes one of the most valuable systems in a modern home – adding particular value to houses built with Modern Methods of Construction.