Modern offsite timber frame homes have become one of the most energy-efficient and climate-resilient building methods available today. While speed, sustainability, and precision manufacturing often get the spotlight, there’s another powerful performance benefit most homeowners and even some specifiers overlook: decrement delay.

In high-performance timber frame construction—especially CLS stud systems, closed-panel solutions, and timber frame wall build-ups—decrement delay plays a major role in keeping homes cooler, more stable, and more comfortable year-round.

In this article, we’ll explain what decrement delay is, why it matters for energy efficiency, and how modern timber frame homes excel compared to traditional building methods.

What Is Decrement Delay in Timber Frame Construction?

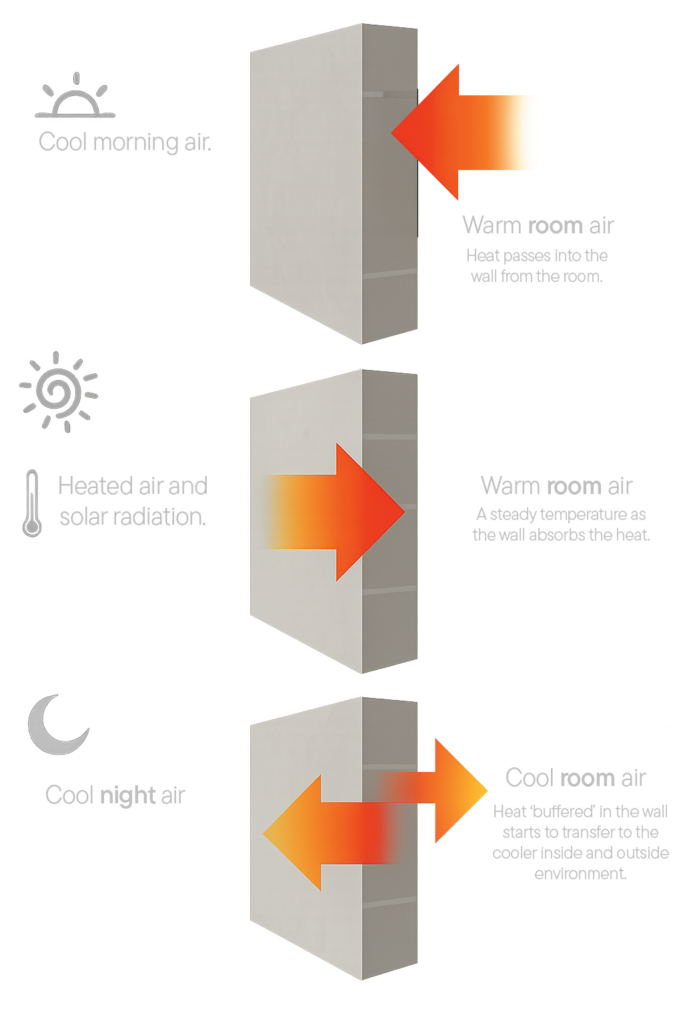

Decrement delay is the measure of how long it takes for external heat (such as solar gain on a hot afternoon) to pass through a wall and influence the indoor temperature.

Put simply:

A high decrement delay = better summer performance + cooler indoor temperatures.

This makes decrement delay a crucial factor in designing low-energy homes, passivhaus-inspired buildings, and modern timber homes with high levels of insulation and airtightness.

Why Timber Frame Homes Offer Excellent Decrement Delay...

Although the term “timber frame” often brings traditional post-and-beam images to mind, novo timber’s offsite timber frame solutions rely on precision engineered panel systems and carefully layered materials to provide superior performance.

These systems can deliver exceptional decrement delay because of their:

1. Multi-layered wall build-up

Our timber frame panels can comprise of a combination of the following components:

CLS stud framework.

Factory-fitted PIR insulation.

- Mineral insulation fitted on-site.

Wood fibre boards.

Vapour control layers.

Service voids ready to receive additional linings.

This layered, breathable build-up slows heat transfer dramatically.

2. Use of high-density insulation materials

Insulation types such as wood fibre, dense-pack cellulose, and hybrid natural insulations provide:

Higher thermal mass

Excellent specific heat capacity

Longer heat storage periods

These materials outperform lightweight insulation found in standard stud wall systems.

3. Precision manufacturing in controlled factory environments

Airtightness, insulation continuity, and panel accuracy are all higher offsite.

Better detailing = stronger thermal performance in real-world conditions.

How does a long decrement delay benefit the homeowner in modern Britain?

❄️ Cooler Homes in ever Hotter Summers.

Walls with 8–12 hours of decrement delay prevent indoor overheating—especially during peak (and rising) summer temperatures.

💰 Lower Energy Bills

Reduced reliance on expensive cooling systems and more stable temperatures mean long-term energy savings.

🛀🏼 Improved Comfort and Indoor Climate

Homes feel calmer and more consistent, with fewer temperature swings and reliance on expensive systems to condition the temperature.

🔥 Reduced Risk of Overheating in Airtight Homes

Modern energy-efficient buildings must manage heat as carefully as cold. Timber frame solutions excel at both.

So how does timber frame fare with decrement delay, when compared to it's traditional alternative?

Because for heavy masonry, the thermal lag is dominated by thermal mass, capacity, and conductivity, not by the small phase-shift effects that decrement delay tries to describe. Decrement delay is a fine concept for lightweight assemblies, but it doesn’t meaningfully influence the thermal behavior of dense, thick masonry walls.

The Real Physics

1. Masonry walls have extremely high thermal mass

Masonry materials (brick, block, concrete) have:

High density

High specific heat

Moderate conductivity

This gives them huge heat-storage capacity, which means:

They buffer heat over long periods (many hours)

They slow down temperature swings naturally

They essentially “average out” daytime and nighttime heat flows

| Construction Method | Typical Decrement Delay | Summer Comfort Level |

|---|---|---|

| Offsite Timber Frame (CLS + wood fibre) | 8–12 hours | Excellent |

| Lightweight masonry cavity walls | 3–6 hours | Moderate |

| Standard stick-built stud walls | 1–2 hours | Poor |

Offsite timber frame clearly outperforms common alternatives—especially when paired with the right insulation strategy.

Why Decrement Delay Is Becoming Essential in Modern Building Design

With rising temperatures and increasingly strict building regulations, summer comfort is becoming just as important as winter efficiency.

High-performance timber frame systems provide:

Lower operational energy use

Better climate resilience

Stronger compliance with overheating assessments (e.g., TM59)

Future-proof thermal performance

As a result, more architects, developers, and homeowners are choosing timber frame construction for long-term comfort and sustainability.

Conclusion: Modern Timber Frame Homes Lead the Way in Thermal Performance

Decrement delay is one of the most powerful—and overlooked—advantages of offsite timber frame homes. With superior wall build-ups, advanced materials, and precision manufacturing, timber frame construction delivers exceptional thermal comfort, reduced overheating, and outstanding energy performance.

One of the key takeaways from Decrement Delay in timber frame is the poor performance of PIR insulation. Whilst PIR might offer strong U Value performance, for retaining that hard earned heat in winter, it will be prone to overheating in the summer due to a very short decrement delay. So it is a balancing act and a key decision during your technical design stage.

If you’re designing or building a home that prioritizes health, comfort, and efficiency, a high-quality timber frame system with optimised decrement delay should be at the top of your list.

FAQs

Q: What exactly is “decrement delay”?

A: Decrement delay is the time lag between when heat (e.g. from the sun or external air) hits the outside surface of a wall or roof, and when that heat begins to affect the inside surface. In other words: how long the building envelope “delays” transferring external temperature changes into the interior. Designing Buildings+22050 Materials+2

Q: How is decrement delay different from a building’s U-value?

A: U-value measures how much heat will eventually pass through a wall or roof under steady conditions (i.e. rate of heat transfer under a constant temperature difference). Decrement delay — on the other hand — matters when temperatures fluctuate over time (e.g. sunny daytime → cooler evening). Two materials might have similar U-values, but very different decrement delay behavior. 2050-materials.com+2backtoearth.co.uk+2

Q: Why is decrement delay important for summer comfort (especially in lightweight / timber-frame homes)?

A: In warm or hot periods, external heat often peaks during the day. Materials with a long decrement delay can postpone heat transmission until later — ideally when outside temps are dropping and you can ventilate or cool the building naturally. That buffering effect helps prevent indoor overheating. unitylime.co.uk+2Planning, Building & Construction Today+2

This makes decrement delay particularly relevant for lightweight constructions (e.g. timber frame) where thermal mass is small and heat passes through quickly. GreenSpec+2Build It+2

Q: What factors influence how long the decrement delay is for a building element?

A: Key factors include the material’s:

- Density — heavier materials tend to slow heat transfer. GreenSpec+1

- Specific heat capacity — materials able to store more heat before changing temperature contribute to greater thermal inertia. GreenSpec+1

- Thermal conductivity — lower conductivity slows heat flow. GreenSpec+1

- Thickness and layering of the wall/roof construction — more mass or thoughtfully arranged layers (e.g. insulation + dense sheathing) can extend delay. GreenSpec+1

Q: What typical delay times are considered “good”?

A: While values vary depending on materials and build-up, a delay of 6–12 hours is often cited as a beneficial range for summer comfort, because it shifts peak heat gain to later in the day or evening when cooling is easier. Planning, Building & Construction Today+22050 Materials+2

Q: Does decrement delay matter equally in all types of construction (timber frame, masonry, insulated concrete, etc.)?

A: No. Decrement delay is most relevant in lightweight or low-mass constructions (e.g. timber-frame homes, insulated roofs, lightweight panels) because these tend to transmit heat quickly and have little thermal mass to buffer. GreenSpec+1

In heavy, dense or massive constructions (e.g. thick masonry or concrete), the thermal mass and inertia already slow and dampen heat transfer — the effect of a “delay” becomes less critical, because the wall naturally buffers and distributes heat over a long period. GreenSpec+2Designing Buildings+2

Q: Are there downsides or limitations to relying on decrement delay for summer overheating prevention?

A: Yes — a few to be aware of:

- If outside temperatures stay high all night (e.g. during heatwaves), then delaying the heat transfer just shifts the discomfort to later — you may still have a hot interior.

- Decrement delay doesn’t substitute for proper ventilation — without night cooling or airflow, buffering alone may not keep spaces comfortable. 2050 Materials+1

- Not all insulation or building materials offer meaningful decrement delay. Some conventional, lightweight insulation products (especially synthetics like foam or fibreglass) have low thermal mass, and so low delay, despite having good U-values. backtoearth.co.uk+1

Q: How can I design a building (or retrofit a home) to take advantage of decrement delay?

A: Some practical strategies:

- Use materials with higher density and specific heat capacity (e.g. wood-fibre, natural insulations, heavy sheathing) rather than just focusing on U-value or thickness. backtoearth.co.uk+22050-materials.com+2

- In a multi-layer wall/roof, arrange layers so the dense, high-mass material is where it can buffer external heat before internal surfaces. GreenSpec+1

- Combine good decrement delay with ventilation strategies (e.g. night purge ventilation) to shed heat before it builds up internally. Planning, Building & Construction Today+1

- In lightweight or timber-frame buildings especially, don’t rely only on synthetic insulation — consider natural or bio-based insulation that tends to offer better thermal mass and delay. Build It+22050-materials.com+2

Q: If I meet building regulations for U-value, do I automatically get good summer comfort?

A: Not necessarily. Building regulations typically focus on steady-state heat loss / gain (winter insulation, U-value). They don’t always account for dynamic heat transfer during fluctuating conditions (daily sun / temperature swings). That’s why decrement delay — and more broadly the thermal dynamics of the envelope — is often overlooked. A low U-value alone does not guarantee summer comfort. backtoearth.co.uk+22050-materials.com+2